Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Study on Effect of Addition of Recycled Bituminous Material to Stone Matrix Asphalt Using Polymer Modified Bitumen (PMB-40)

Authors: Er. Digwant Kumar Mahto, Er. Ajay Kumar Duggal

DOI Link: https://doi.org/10.22214/ijraset.2025.66225

Certificate: View Certificate

Abstract

Stone Matrix Asphalt (SMA) is a gap-graded mix with a high proportion of coarse aggregate, binder, and fiber additives for stability. A high concentration of coarse aggregate enhances stone-on-stone contact and interlocking, resulting in strength and durability. Stabilizing additives prevent bitumen draindown material. This study assesses the influence of incorporating Recycled Asphalt Pavement (RAP) into Stone Matrix Asphalt (SMA) along with Polymer Modified Bitumen (PMB-40) in road construction to increase performance and sustainability. The study aims to determine the optimal binder content and evaluate the mechanical properties of SMA mixtures using varied RAP percentages (0%, 15%, 20%, and 25%) and cellulose fibers. The study also looks at important performance indicators such as Marshall Stability, Draindown characteristics, Indirect Tensile Strength (ITS), and Tensile Strength Ratio (TSR). The results indicate that the optimum binder content for RAP-modified SMA falls between 6.2% and 6.4%. The addition of RAP improved the mechanical performance, with RAP-modified mixes demonstrating a 5–7% increase in Marshall Stability and a 15–20% improvement in ITS as compared to control samples. Superior resistance to moisture-induced damage and cracking can be seen by TSR values that continuously exceed the mandatory minimum of 0.90. The combination of 15-25% RAP and 0.3% cellulose fibers significantly reduced draindown, ensuring proper binder retention during mixing and placement. These results show that by adding RAP to SMA mixes not only helps to preserve natural-environmental resources but also improves durability and resistance to environmental pressures. The study supports continued efforts to create environmentally friendly infrastructure by confirming that recycled bituminous materials can be used without sacrificing structural integrity.

Introduction

I. INTRODUCTION

Throughout the world, bitumen-bound aggregates are commonly used in flexible pavement construction and maintenance, typically in the form of dense, well-graded, or coarse-graded mixes. However, assessing these mixes may not always be feasible at all construction sites. In such cases, Stone Matrix Asphalt (SMA), a gap-graded mix, serves as an effective alternative.

SMA was first introduced in Europe during the late 1960s and early 1970s to address pavement damage caused by studded tires. Subsequent studies confirmed its exceptional ability to resist deformation under heavy traffic and wheel loads. Over time, SMA has been widely adopted globally, delivering consistently superior results. This asphalt mixture contains approximately 70–80% coarse aggregates, 6–7% bitumen, 8–12% fillers, and at least 0.3% fiber content. Its gap-graded design forms a skeleton-like framework, providing superior stone-on-stone contact among coarse aggregates. This feature significantly enhances its resistance to rutting. Unlike dense-graded mixes, where finer aggregates facilitate load transfer, SMA primarily relies on coarse aggregates to distribute loads. Its higher bitumen content makes SMA more durable than traditional asphalt layers. Additionally, the fibers in the mix prevent bitumen draindown during transportation, ensuring the binder remains intact. The Federal Highway Administration (FHWA) describes SMA as "a gap-graded aggregate hot mix asphalt (HMA) that maximizes the coarse aggregate fraction and bitumen content while forming a stable stone-on-stone skeleton held together by a rich blend of bitumen, filler, and stabilizing additives." Recycled Asphalt Pavement (RAP), obtained from deteriorated pavements, is a sustainable material that can be reused as a partial substitute for virgin aggregates. Incorporating RAP in SMA mixtures not only improves performance but also minimizes environmental impact, aligning with sustainable construction practices.

II. NEED AND SCOPE OF STUDY

A. Need For Study

Road transportation is becoming increasingly important. To meet current transportation needs, new roads must be built as well as existing ones improved. Despite the fact that numerous agents and filler materials have been used in SMA to find the Indirect Tensile Strength and Draindown Test. This study is ahead of them in determining the effect of incorporating recycled bituminous material on Indirect Tensile Strength and Draindown properties.

Recycling is one of important factors to be considered in the present situation. Dumping of waste materials causes land requirement. By using some amount of RAP percentage in the SMA Mix, there is reduction in amount of virgin material to be used and reduction in cost as well. Considering these facts an attempt has been made to study the behaviour of SMA Mix with RAP and addition of fiber to it using PMB-40.

B. Scope And Objectives Of Present Study

Conducting a Draindown test and TSR (Tensile Strength Ratio) test on Stone Asphalt (SMA) with recycled bituminous materials offers a broad scope for understanding its performance. The draindown test assesses the asphalt mix's ability to retain its binder during transport and construction, crucial for ensuring proper coating of aggregates. Meanwhile, TSR evaluates the resistance of the asphalt mixture to cracking.

This research has the potential to contribute to the development of environmentally friendly road construction practices, addressing issues like binder drainage and tensile strength in recycled material-based SMA. The findings can guide the industry toward more sustainable and durable asphalt solutions.

The main objectives of the present study are;

- To determine optimum binder content of Stone Matrix Asphalt SMA (Grade-1) using controlled mix.

- To determine optimum content of Recycled Bituminous Material at optimum binder content.

- To determine optimum content of cellulose fiber at optimised amount of Recycled Bituminous Material and optimised binder content.

- To determine the Tensile Strength Ratio (TSR) and Draindown properties of mix prepared for Stone Matrix Asphalt (Grade-1) at optimum binder content for Polymer modified bitumen (PMB-40) and compare with controlled mix.

III. MATERIAL PROPERTIES EVALUATION

A. Aggregates

Aggregates measuring 19mm, 10 mm, and 6.7 mm and stone dust were used. The materials used satisfied all general requirements as per MORT&H (5th revision) and IRC: SP: 79-2023. The aggregates were collected from the nearby road construction site. The tests which have been done on aggregates are displayed in Table 1

Table 1: Physical Properties of Coarse and Fine Aggregates including RAP

|

Physical properties |

19mm |

10mm |

6.7 mm |

Fillers |

RAP |

Required values as per IRC: SP: 79-2023 |

||

|

Impact value (%) |

17.2 |

16.8 |

16.6 |

|

15% |

20% |

25% |

Max 18% |

|

16.88 |

15.92 |

15.64 |

||||||

|

Specific Gravity |

2.547 |

2.590 |

2.607 |

2.668 |

|

2.6-2.8 |

||

|

Water absorption (%) |

0.45 |

0.55 |

0.62 |

0.86 |

2 |

Max 2% |

||

|

Combined Elongation and Flakiness Index (%) |

23 |

24.6 |

22.8 |

|

|

Max 30% |

||

B. Binder

The right selection of binder has an impact to the stone skeleton's performance. In this research, polymer modified bitumen (PMB-40) is used. To determine the physical characteristics of bitumen, different tests are performed in accordance with IS 15462:2004. The binder PMB-40 is obtained from Hindustan Colas Pvt. Limited, Bahadurgarh, Haryana and the test results are reported in Table 2

Table 2: Properties of Polymer Modified Bitumen (PMB-40) grade binder.

|

S.N. |

Characteristics |

Results |

Requirements |

Method of Test |

|

1 |

Penetration at 25?C, 0.1mm, 100g, 5 sec |

45 |

30-49 |

IS: 1203-1978 |

|

2 |

Softening Point, (R&B), ?C Minimum |

62 |

59 |

IS: 1205-1978 |

|

3 |

Ductility at 27?C, cm, Minimum |

33 |

30 |

IS: 1208-1978 |

|

4 |

Flash Point, COC, ?C Minimum |

222 |

220 |

IS: 1209-1978 |

|

5 |

Separation, difference in softening point, R&B, ?C, Maximum |

3 |

3 |

ASTM D5976-1996 |

|

6 |

Viscosity at 150?C, Poise |

6.5 |

4-8 |

IS: 1206-1978 |

|

7 |

Specific Gravity |

1.02 |

>0.99 |

IRC: SP: 53-2010 |

C. Mineral Filler

Stone dust has been used as the mineral filler in the stone matrix asphalt mixture, with the replacement for hydrated lime in the percentage range of 8-12%%. It was procured from nearby site in Chandigarh.

The sieve analysis of stone dust and test results as shown in Table 3

Table 3: Sieve analysis of Stone dust.

|

Sieve Size (mm) |

Weight Retained (g) |

Percent Weight Retained (%) |

Cumulative Percent Weight Retained (%) |

Cumulative Percent Weight Passing (%) |

Lower Limit (%) |

Upper Limit (%) |

|

0.6 |

2 |

1 |

1 |

100 |

100 |

100 |

|

0.3 |

10 |

5 |

6 |

98.3 |

95 |

100 |

|

0.075 |

13 |

6.5 |

12.5 |

86 |

85 |

100 |

D. Fiber (Cellulose Fiber)

Fibers are used as stabilizer in SMA mixture. It helps to increase the strength and stability also decrease the drain down in SMA Mix. In the present study, the fiber used is Cotton-cellulose fiber. It was procured from VK Minerals and Chemicals, Tronica City, Ghaziabad. Cotton-cellulose is a soft and absorbent fiber that is obtained from the seeds of the cotton plant and it is a powdery to fibrous cellulose additive for use in construction chemicals products.

IV. EXPERIMENTAL INVESTIGATIONS

A. Aggregate Gradation

To achieve the proper blend, aggregates of varying sizes were used, including 19mm, 10mm, 6mm, and stone dust as filler material. A total of 4000 grams of aggregates were subjected to sieve analysis. Aggregate gradation was performed using Rothfuch’s Method to determine the individual percentages of different aggregate sizes, ensuring compliance with the upper and lower limits specified in MoRTH Table 500-37 and IRC: SP:79:2023. Gradation charts were prepared for both conventional SMA and SMA mixes. The grading of materials for different mix type is shown in Table 4

Table 4: Grading of aggregate and mix for different SMA mix type

|

IS Sieve (mm) |

19mm |

10mm |

6.7mm |

Stone Dust as filler |

RAP |

Grading of Mix |

Cumulative % by weight total aggregate passing |

|||

|

Control Mix |

Mix with 15% RAP |

Mix with 20% RAP |

Mix with 25% RAP |

|||||||

|

26.5 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

- |

|

19 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

13.2 |

74.6 |

98.7 |

100 |

100 |

85 |

94.41 |

93.23 |

92.8 |

92.3 |

90-100 |

|

9.5 |

7.4 |

65.6 |

100 |

100 |

60 |

68.06 |

67.14 |

66.4 |

66.4 |

50-75 |

|

4.75 |

0 |

8.3 |

35.4 |

100 |

35 |

26.15 |

26.65 |

26.6 |

27.8 |

20-28 |

|

2.36 |

0 |

4 |

15 |

100 |

25 |

18.76 |

18.75 |

18.7 |

19.6 |

16-24 |

|

1.18 |

0 |

1.7 |

2.3 |

100 |

18 |

14.31 |

13.85 |

13.7 |

14.5 |

13-21 |

|

0.6 |

0 |

0 |

1 |

100 |

14 |

13.28 |

12.34 |

12 |

12.7 |

12-18 |

|

0.3 |

0 |

0 |

0 |

98.5 |

6 |

12.78 |

10.75 |

10.1 |

10.4 |

10-20 |

|

0.075 |

0 |

0 |

0 |

90 |

0 |

11.18 |

9 |

8.1 |

8.1 |

8-12 |

B. SMA Mix Design

The mix design was carried out using the Marshall Stability Test to determine the optimum binder content, RAP replacement percentage, and fiber content, ensuring maximum stability values. The design also adhered to other Marshall parameters. The mix was designed to meet the specifications outlined in MoRTH Table 500-38: SMA Mix Requirements. The samples are prepared in accordance with ASTM D6926: Standard Practice for Preparation of Bituminous Specimens Using Marshall Apparatus. 50 blows are required on each face of the specimen for SMA mixes.

Table 5 shows the proportion of 19mm, 10mm, 6.7mm, Filler and RAP for different SMA mix type.

Table 5: Proportion of materials in percentage including RAP for SMA mix type

|

|

Control Mix (%) |

Mix with 15% RAP (%) |

Mix with 20% RAP (%) |

Mix with 25% RAP (%) |

|

19mm |

20 |

16 |

15 |

14 |

|

10mm |

39 |

35 |

34 |

31 |

|

6.7mm |

28 |

24 |

22 |

21 |

|

Stone Dust as filler |

13 |

10 |

9 |

9 |

|

RAP |

? |

15 |

20 |

25 |

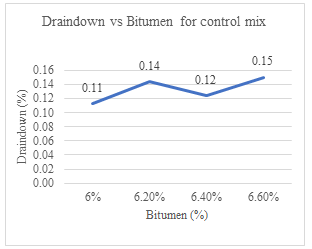

1) Conventional SMA Mix

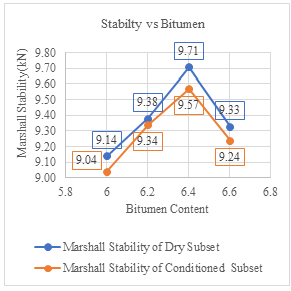

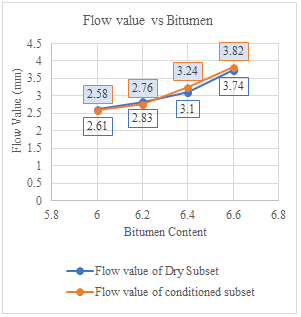

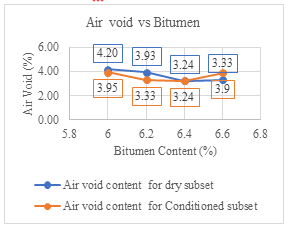

The Marshall Stability test was carried out in the lab to determine the ideal binder content and stability for conventional SMA mix. Samples were prepared with minimum bitumen of 6% and subsequently with an increment of 0.2% and going up to 6.6%. Table 6 displays the test findings, Figure 1, Figure 2, Figure 3 and Figure 4 display the Marshall Parameters of Stability, Flow Value, Air Void and Density of mix vs Bitumen Content. According to IRC: SP: 79: 2023 Specifications for Stone Matrix Asphalt, the volumetric properties with binder content (%) for ordinary mixes are within acceptable bounds. According to research on engineering properties, the ideal bitumen concentration for a traditional SMA mix was determined to be 6.2%.

Table 6: Marshall Properties for Conventional SMA Mix

|

|

Unconditioned subset |

Conditioned subset |

||||||

|

Bitumen Content (%) |

6% |

6.20% |

6.40% |

6.60% |

6% |

6.20% |

6.40% |

6.60% |

|

Gt (g/cc) |

2.32 |

2.32 |

2.33 |

2.32 |

2.32 |

2.33 |

2.33 |

2.30 |

|

Gm (g/cc) |

2.66 |

2.66 |

2.66 |

2.66 |

2.66 |

2.66 |

2.66 |

2.66 |

|

Vv (%) |

4.20 |

3.93 |

3.24 |

3.33 |

3.95 |

3.33 |

3.24 |

3.90 |

|

Vb (%) |

13.91 |

14.37 |

14.89 |

15.30 |

13.94 |

14.46 |

14.89 |

15.21 |

|

VMA (%) |

18.10 |

18.30 |

18.13 |

18.62 |

17.89 |

17.78 |

18.13 |

19.11 |

|

VFB (%) |

76.81 |

78.51 |

82.13 |

82.14 |

77.94 |

81.28 |

82.13 |

79.58 |

|

Flow Value (mm) |

2.61 |

2.83 |

3.10 |

3.74 |

2.58 |

2.76 |

3.24 |

3.82 |

|

Stability value (kN) |

9.14 |

9.38 |

9.71 |

9.33 |

9.04 |

9.34 |

9.57 |

9.24 |

|

ITS Value (kN/mm²) |

0.64 |

0.66 |

0.74 |

0.71 |

0.61 |

0.59 |

0.69 |

0.67 |

|

TSR |

0.95 |

0.89 |

0.93 |

0.94 |

|

|

|

|

Figure 1: Marshall stability vs Bitumen content for conventional mix

Figure 2: Flow Value vs Bitumen content for conventional mix

Figure 3: Air Void vs Bitumen content for conventional mix

Figure 4: Density vs Bitumen content for conventional mix

2) SMA Mix with different proportion of RAP

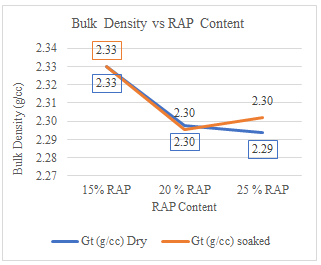

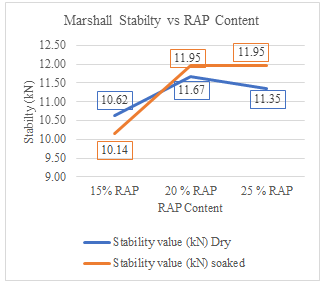

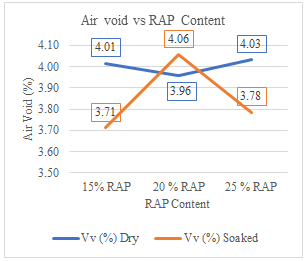

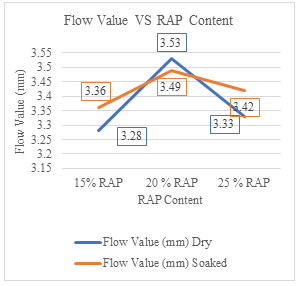

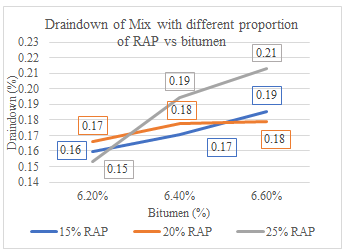

The incorporation of Reclaimed Asphalt Pavement (RAP) into Stone Matrix Asphalt (SMA) mixes was evaluated based on Marshall properties. RAP dosage levels were varied across 15%, 20%, and 25%, with the bitumen content adjusted within the same range as observed in conventional SMA mixes. The gradation corresponding to these RAP percentages was previously discussed.

Experimental investigations revealed that the optimum RAP content for the SMA mix was 20%. At this dosage, the Marshall properties were observed to be superior compared to those at 15% and 25% RAP. Consequently, the 20% RAP dosage was selected for further studies to determine the fiber content and optimum bitumen content required for assessing various engineering properties.

The results of these assessments are summarized in Table 7, and the corresponding graphical representations are illustrated in, Figure 5, Figure 6, Figure 7and Figure 8 for Bulk density, Air void, Stability and flow value respectively.

Table 7: Marshall properties of Unconditioned and Conditioned subset for mix with different proportion of RAP at Optimum Binder content of 6.4%

|

Unconditioned Subset |

Conditioned Subset |

|||||

|

15% RAP |

20 % RAP |

25 % RAP |

15% RAP |

20 % RAP |

25 % RAP |

|

|

Gt (g/cc) |

2.33 |

2.3 |

2.29 |

2.33 |

2.3 |

2.3 |

|

Gm (g/cc) |

2.69 |

2.64 |

2.64 |

2.68 |

2.64 |

2.64 |

|

Vv (%) |

4.01 |

3.96 |

4.03 |

3.71 |

4.06 |

3.78 |

|

Vb (%) |

14.91 |

14.71 |

14.71 |

14.91 |

14.69 |

14.73 |

|

VMA (%) |

18.93 |

18.66 |

18.71 |

18.62 |

18.75 |

18.52 |

|

VFB (%) |

78.79 |

78.79 |

78.45 |

80.07 |

78.37 |

79.56 |

|

Flow Value (mm) |

3.28 |

3.53 |

3.33 |

3.36 |

3.49 |

3.42 |

|

Stability value (kN) |

10.62 |

11.67 |

11.35 |

10.14 |

11.95 |

11.95 |

|

ITS Value (kN/mm²) |

0.74 |

0.72 |

0.7 |

0.67 |

0.68 |

0.64 |

|

TSR |

0.91 |

0.94 |

0.92 |

|||

Figure 5: Bulk Density vs Different RAP Content

Figure 6: Marshall Stability vs Different RAP Content

Figure 7: Air Void vs Different RAP Content

Figure 8: Flow Value vs Different RAP Content

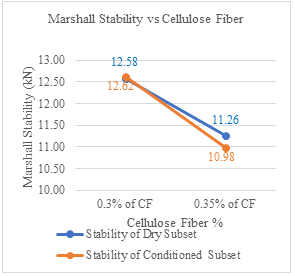

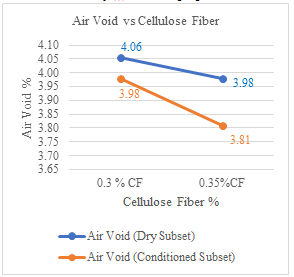

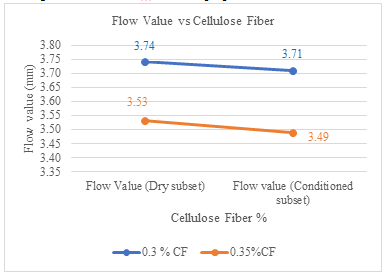

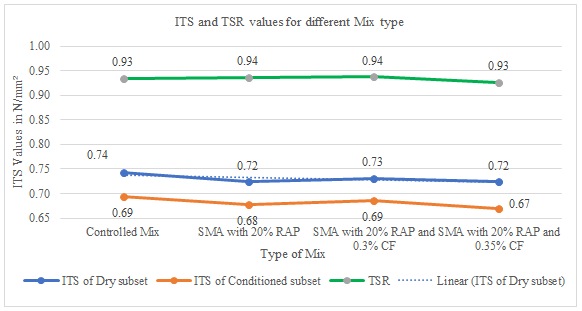

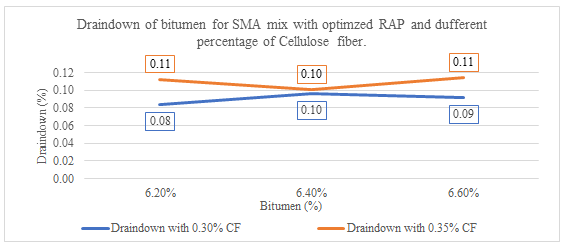

3) SMA Mix with Optimized RAP and Fiber

This section focuses on determining the optimum dosage of fiber for use in the SMA (Stone Matrix Asphalt) mix. Fiber dosages were varied between 0.3% and 0.35%, while the bitumen concentrations used in the mix were 6.0%, 6.2%, 6.4%, and 6.6%. The optimum bitumen content (OBC) required for further investigations was also determined in this study.

Experimental results indicated that the maximum stability and other Marshall parameters were achieved at a bitumen content of 6.4%. The optimum fiber dosage for the mix was observed to be 0.3%, while the optimum bitumen content (OBC) for further evaluation of engineering properties was identified as 6.4%.

The results of these investigations are summarized in

Table 8, with the corresponding Marshall properties illustrated in Figure 9, Figure 10, Figure 11 and Figure 12.

Table 8: Marshall Properties for SMA Mix with optimized RAP and fiber

|

Unconditioned subset |

Conditioned subset |

Unconditioned subset |

Conditioned subset |

|

|

Fiber Addition (cellulose fiber) |

0.30% |

0.30% |

0.35% |

0.35% |

|

Gt (g/cc) |

2.30 |

2.30 |

2.30 |

2.30 |

|

Gm (g/cc) |

2.64 |

2.64 |

2.64 |

2.64 |

|

Vv (%) |

4.06 |

3.98 |

3.98 |

3.81 |

|

Vb (%) |

14.69 |

14.70 |

14.70 |

14.73 |

|

VMA (%) |

18.75 |

18.68 |

18.68 |

18.54 |

|

VFB (%) |

78.37 |

78.70 |

78.70 |

79.46 |

|

Flow Value (mm) |

3.74 |

3.71 |

3.53 |

3.49 |

|

Stability value (kN) |

12.58 |

12.62 |

11.26 |

10.98 |

|

ITS Value (kN/mm²) |

0.73 |

0.69 |

0.72 |

0.67 |

|

TSR |

0.94 |

0.93 |

||

Figure 9: Marshall Stability vs different proportion of Cellulose fiber

Figure 10: Air Void vs different proportion of Cellulose fiber

Figure 11: Marshall Stability vs different proportion of Cellulose fiber

Figure 12: ITS and TSR values for different mix type

4) Draindown Test

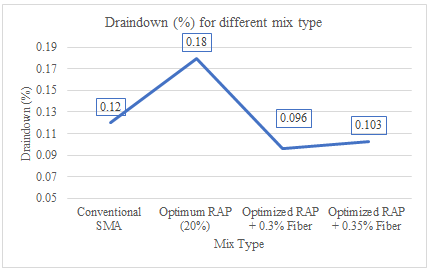

Draindown of binder is one of the most common features observed in gap-graded bituminous mixes such as Stone Matrix Asphalt and hence the effect of binder content on draindown characteristics of un-compacted fresh mix is an important parameter to address. This test was done in order to assure that binder drain off does not exceed 0.3%. The Draindown characteristics for the SMA mix were conducted for the conventional SMA mixes as well as for the SMA mix with optimized RAP and fiber as obtained above, the results are tabulated in the Table 9 and shown in, Figure 13, Figure 14, Figure 15 and Figure 16.

Table 9: Drain down Potential Test Results Mix Type

|

Drain down Potential Test Results Mix Type |

Draindown (%) |

|

Conventional SMA |

0.12 |

|

Optimum RAP (20%) |

0.18 |

|

Optimized RAP + 0.3% Fiber |

0.096 |

|

Optimized RAP + 0.35% Fiber |

0.103 |

Figure 13: Draindown of control mix for different percentage of bitumen

Figure 14: draindown of mix with different proportion of RAP vs bitumen

Figure 15: Draindown of bitumen for SMA mix with optimized RAP and different percentage of cellulose fiber.

Figure 16: Draindown for different mix type at OBC.

V. RESULTS AND DISCUSSION

A. Marshall Properties

1) Conventional Mix

- The SMA mix with PMB-40 shows optimal Marshall Stability at 6.4% bitumen content, balancing stability, air voids (3.33%–3.94%), and flow values (2.61–3.82 mm). Higher bitumen increases flow, enhancing flexibility but risking deformation.

2) Mix with RAP

- 15% RAP: Maximum stability occurs at 6.4% bitumen content, with air voids ranging from 3.29% to 4.01%. Flow values (3.1–3.48 mm) rise with bitumen, indicating flexibility but possible rutting.

- 20% RAP: Stability peaks at 6.4% bitumen, with air voids from 3.01% to 4.06%. Flow values (3.38–3.81 mm) remain acceptable, showing optimal balance at 6.4%.

- 25% RAP: Stability and flow are optimal at 6.4% bitumen, with air voids between 3.01% and 4.06%. A slight stability drops at 6.6% suggests 6.4% as the ideal content.

3) Mix with Optimized RAP and Cellulose Fiber

- 0.30% CF: The addition of 0.3% cellulose fiber enhances stability, achieving optimal Marshall Stability (11.95–12.62 kN) at 6.4% bitumen content. Flow values increase with bitumen (3.63–3.88 mm), while air void content peaks at 6.4%, ensuring durability. Uniform density indicates structural integrity and effective reinforcement by the fiber.

- 0.35% CF: Higher bitumen content improves workability but reduces stability under load, with decreased Marshall Quotient and Indirect Tensile Strength at 6.6% bitumen. Optimal performance occurs at 6.2% bitumen, balancing stability and flow. Increased air voids and reduced tensile strength at higher bitumen content suggest potential durability concerns under traffic loads.

B. Draindown Characteristics

- Control Mix: Draindown increases with bitumen content, peaking at 0.15% for 6.6% binder. A decrease is observed at 6.4%, with a minimum value of 0.12%.

- Mix with RAP: Draindown rises with increasing bitumen content but stabilizes at 6.4% before increasing at 6.6%. Higher RAP percentages increase binder drainage, highlighting the need for optimized bitumen content.

- Mix with Optimized RAP and Cellulose Fiber: Adding 0.3%–0.35% cellulose fiber controls draindown effectively, with optimal performance at 6.2%–6.4% bitumen. Higher fiber content reduces draindown slightly but requires balance with bitumen for durability.

Conclusion

Based on the interpretation of the tests conducted on Stone Matrix Asphalt (SMA) using Polymer Modified Bitumen (PMB-40) with cellulose fiber: The tests revealed that the optimal bitumen content for stability in both conventional and RAP-modified mixes hovers around 6.4%. To balance between stability, flow, and void content this composition of material offers good resistance to deformation as well as also satisfying flexibility. The addition of Reclaimed Asphalt Pavement (RAP) influences these characteristics, with the maximum RAP content (25%), resulting in somewhat lower stability at higher bitumen amounts (6.6%). A small amount of cellulose fiber, especially at 0.3% and 0.35%, improves mix stability and decreases draindown at elevated temperatures. However, as the bitumen content increases, the efficiency of cellulose fiber in controlling draindown drops. The fiber contributes to structural integrity and load-bearing capacity, particularly at optimal bitumen levels of 6.2% to 6.4%. In conclusion, the study suggests that maintaining the bitumen content within the 6.2% to 6.4% range provides the best balance of stability, flow, and durability, while adding cellulose fiber further enhances the mix’s resistance to deformation and draindown. However, careful consideration of the fiber and bitumen balance is necessary to achieve the desired performance under varying traffic and environmental conditions.

References

[1] Alshehri, H. A., Al Abdul Wahhab, H. I., Dalhat, M. A., Al-Juhani, A. H. A., & Al-Osta, M. A. (2023). Recycled polyethylene waste as binder stabilizer for SMA mix in gulf environment. Case Studies in Construction Materials, 18. https://doi.org/10.1016/j.cscm.2023.e02177 [2] Alshehri, H. A., Wahhab, H. I. A. A., & Al-Osta, M. A. (2023). Performance of SMA Mix modified with waste plastic and fiber. Case Studies in Construction Materials, 19. https://doi.org/10.1016/j.cscm.2023.e02566 [3] Fakhri, M., Shahryari, E., & Ahmadi, T. (2022). Investigate the use of recycled polyvinyl chloride (PVC) particles in improving the mechanical properties of stone mastic asphalt (SMA). Construction and Building Materials, 326. https://doi.org/10.1016/j.conbuildmat.2022.126780 [4] Gallo, P., Belhaj, M., & Valentin, J. (2024). Laboratory Study of Asphalt Concrete for Base Course with Reclaimed Asphalt, Recycling Agents, and Jute Fibres. Applied Sciences (Switzerland), 14(1). https://doi.org/10.3390/app14010239 [5] Guo, Y., Tataranni, P., Tarsi, G., & Sangiorgi, C. (2024). Performance evaluation of stone mastic asphalt reinforced with shredded waste E-cigarette butts. Case Studies in Construction Materials, 20. https://doi.org/10.1016/j.cscm.2024.e03126 [6] Irfan, M., Ali, Y., Ahmed, S., Iqbal, S., & Wang, H. (2019). Rutting and Fatigue Properties of Cellulose Fiber-Added Stone Mastic Asphalt Concrete Mixtures. Advances in Materials Science and Engineering, 2019. https://doi.org/10.1155/2019/5604197 [7] Jagadeesh, H. S., & Kadayyanvarmath, M. (2015). Studies on SMA Mixes with Partial Rap Replacement in Addition with Fiber. In International Journal of Science and Research (Vol. 6). www.ijsr.net [8] Mashaan, N., Chegenizadeh, A., & Nikraz, H. (2022). Performance of PET and nano-silica modified stone mastic asphalt mixtures. Case Studies in Construction Materials, 16. https://doi.org/10.1016/j.cscm.2022.e01044 [9] Panda, M., Suchismita, A., & Giri, J. (2013). Utilization of Ripe Coconut Fiber in Stone Matrix Asphalt Mixes. International Journal of Transportation Science and Technology, 2(4), 289–302. https://doi.org/10.1260/2046-0430.2.4.289 [10] Sarang, G., Lekha, B. M., Krishna, G., & Ravi Shankar, A. U. (2016). Comparison of Stone Matrix Asphalt mixtures with polymer-modified bitumen and shredded waste plastics. Road Materials and Pavement Design, 17(4), 933–945. https://doi.org/10.1080/14680629.2015.1124799 [11] Tataranni, P., & Sangiorgi, C. (2021). A preliminary laboratory evaluation on the use of shredded cigarette filters as stabilizing fibers for stone mastic asphalts. Applied Sciences (Switzerland), 11(12). https://doi.org/10.3390/app11125674 [12] Van Thanh, D., Cheng, *, & Feng, P. (2013). Influence of different fibers on high temperature and water stability of stone matrix asphalt. In International Journal of Applied Engineering and Technology (Vol. 3, Issue 1). http://www.cibtech.org/jet.htm [13] Wu, M. M., Li, R., Zhang, Y. Z., Fan, L., Lv, Y. C., & Wei, J. M. (2015). Stabilizing and reinforcing effects of different fibers on asphalt mortar performance. Petroleum Science, 12(1), 189–196. https://doi.org/10.1007/s12182-014-0011-8 IRC Standards, ASTM Standards [1] IRC: 120-2015 Recommended practice for recycling of bituminous pavements, New Delhi, Indian Roads Congress, June 2015. [2] IRC: SP:79- 2023 Specifications for stone matrix asphalt (first Revision), Indian Roads Congress, New Delhi, December 2023 [3] AASHTO: MP 8 Standard Specification for Stone Matrix Asphalt (SMA) American Association of State Highway and Transportation Officials (AASHTO), Washington DC, 2007. [4] QIS: 122 Designing and Constructing SMA Mixtures— State-of-the-Practice, National Asphalt Pavement Association, Maryland, Revised 03/02. [5] T 166 Bulk specific gravity of compacted asphalt mixtures using saturated surface-dry specimens. American Association of State Highway and Transportation Officials (AASHTO), Washington DC, 2022. [6] AASHTO T 283 Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage, American Association of State Highway and Transportation Officials (AASHTO), Washington DC, 2022. [7] MORTH-Specifications for road and bridge work (5th Revision), Indian Road Congress, New Delhi, 2013 [8] ASTM D6926-20: Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus Other References [1] Duggal Ajay K., “Types of highway construction (for flexible pavements)”, 2013 (NITTTR). [2] H.P. Bitumen Handbook (2002).

Copyright

Copyright © 2025 Er. Digwant Kumar Mahto, Er. Ajay Kumar Duggal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET66225

Publish Date : 2025-01-01

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online